Price of common copper electrodes

Features of common brazing electrodes:

T107 is copper welding rod, which has good corrosion resistance to atmosphere and sea water. It is mainly used to weld copper structural parts such as conducting copper bar and conduit. The chemical composition of the deposited metal / simncu 0.50.599 t207 is a silicon bronze electrode. For inorganic acid (except nitric acid), organic acid has corrosion resistance, suitable for welding copper, silicon bronze and brass. Chemical composition of deposited metal / simnpppbcu 2.5-4.0 < 3.00.300.02 > 95

T227 is phosphor bronze electrode, with certain strength, plasticity, toughness, wear resistance and corrosion resistance, suitable for welding of copper, brass, phosphor bronze, etc. Chemical composition of deposited metal / snpcu 0.50.05-0.3 margin

T237 is an aluminum manganese bronze electrode with excellent wear resistance and corrosion resistance. It is widely used in the welding of copper alloy, aluminum bronze, copper and cast iron. Chemical composition of deposited metal / simnalcu 0.12.07.0-9.0 margin

T247 high manganese aluminum bronze is a copper alloy electrode with core and coating of low hydrogen type. Excellent wear resistance and corrosion resistance. DC power supply is adopted, and electrode is connected with positive pole. Application: used for welding of high manganese aluminum bronze and other copper alloy, copper alloy and steel and repairing welding of cast iron. Such as all kinds of chemical machinery, sea water radiator, valve welding, water pump, cylinder stack welding and ship propeller repair. Chemical composition of deposited metal / mnfenialcu 9.0-12.02.5-4.01.8-2.55.5-7.5 margin

T302 titanium calcium type coating Cu70Ni30 white copper welding strip, can be used for both AC and DC, full position welding. The welding process is excellent, and the weld metal has good plasticity and crack resistance. Application: mainly used for welding 70-30 Cu Ni alloy. It can also be used for stack welding of carbon steel parts, deposited metal chemical composition / mnfesinippbti, other Cu 1.0-2.50.4-0.750.529-330.020.020.500.5 allowance

Copper base solder series:

High price and large quantity supply of brass electrode: common brand HS221, copper zinc alloy solder, mainly used for gas flame, high frequency, resistance, furnace medium brazing method, brazing copper, copper alloy, steel, cast iron, hard alloy, etc.

High price large supply of manganese brass welding material, brand HL105, higher strength than brass electrode, better material, shape wire, piece, welding piece (0.420, 0.240), melting temperature 880 ° 910 ° C, is commonly used in cemented carbide industry, with the advantages of high strength, low cost, now widely used in cutting tools, saw blades, mining tools, and other products with high strength requirements. Welding.

We have special strength requirements of phosphor copper, oxygen free copper, copper solder (wire, electrode, welding ring) silver free wire.

Copper phosphorus brazing filler metal is based on copper, phosphorus binary alloy and copper phosphorus silver ternary alloy. It has good liquidity. It is suitable for contact brazing, gas flame brazing, high frequency brazing and furnace brazing. Adding silver into copper phosphorus alloy can greatly improve the wettability of solder, improve the toughness of strength and reduce the melting point. Widely used in refrigerators, air conditioners and other refrigeration industries, as well as Electromechanical, electrical appliances, instruments and other manufacturing industries.

Product specification:

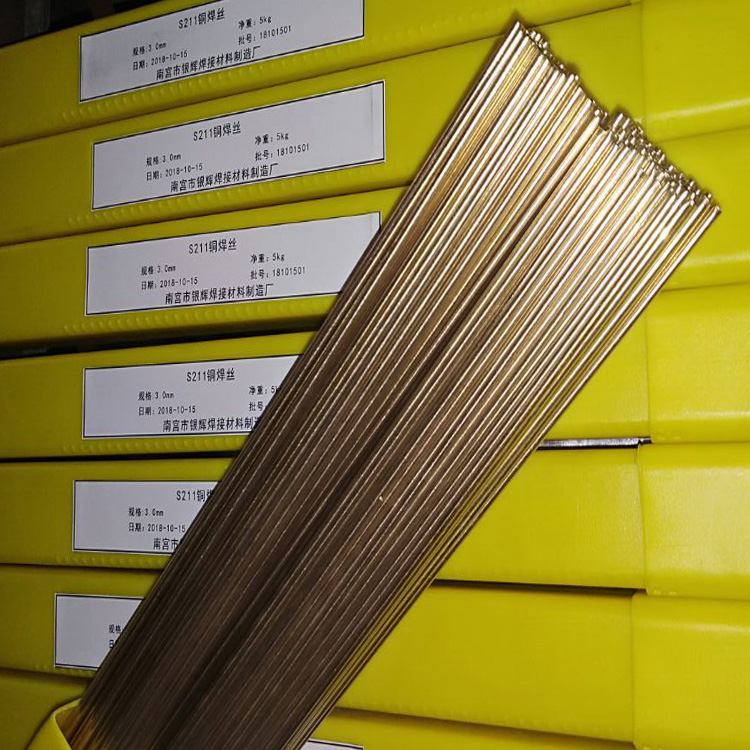

1. Welding wire series: 0.8-3.0mm coil wire

2. Electrode series: 0.8-4.0mm straight bar 1.33.15mm flat electrode

3. Welding ring series: wire diameter: 0.8-2.5mm, inner diameter more than 3.5mm, various specifications of welding rings, mainly to meet the use of automatic welding production line.

Storage method of welding rod

1. All kinds of welding rods must be classified and stacked by brand to avoid confusion.

2. The welding rod must be stored in a dry warehouse. It is recommended that the room temperature be below 10 & deg; C and the relative humidity be less than 60.

3. All kinds of welding rods must be stored 300 mm above the ground and 300 mm above the wall to avoid moisture.

4. Generally, the quantity of welding rod out of warehouse at one time cannot exceed the quantity of two days. The welding rod that has been out of warehouse must be kept well.

The difference between copper electrode and silver electrode

The main chemical composition of the brazing strip: P: 6.8-7.2, Cu: residual performance: brazing temperature 710-810, low melting point, good fluidity, low cost, silver saving and silver substitute. Application: suitable for the welding of copper and copper pipe joints in the refrigeration system of air conditioner, refrigerator and refrigerator

Silver electrode is a kind of electrode with silver or silver based solid body, which has excellent process performance, low melting point, good wettability and ability to fill the gap, high strength, good plasticity, excellent conductivity and corrosion resistance. It can be used to braze all ferrous and non-ferrous metals except aluminum, magnesium and other low melting point metals. This product is widely used in refrigeration, lighting, lighting, etc. Hardware and electrical appliances, instruments and meters, chemical industry, aerospace and other industrial manufacturing fields.

English

English

简体中文

简体中文